Many businesses view custom branded uniforms as a simple commodity—a checkbox item for the procurement department. This perspective is a fundamental business error. Your team’s uniform is a primary vehicle for brand equity and is often the first visual data point a prospective client processes.

A compromised logo on your uniform signals a compromised standard in your business operations.

At elo works, we do not view embroidery as mere decoration; we view it as engineering. To understand the ROI of your custom branded uniforms, one must understand the technical distinction between "Industry Average" and "Professional Standard." If you are seeking to explore our full range of execution methods, you can review Our Customization Page before continuing to the technical details.

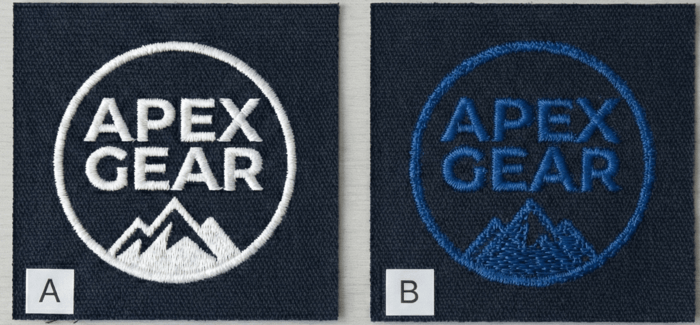

The flaws visible here are not accidental; they are symptomatic of cost-cutting measures:

Poor Tension Calibration: Notice the looping threads. This occurs when machine tension is not adjusted for the specific tensile strength of the thread used.

Gapping: You can see the fabric of the garment peeking through the stitching. This is a result of low stitch density—a tactic used to save thread and reduce machine run-time.

Lack of Definition: The edges of the lettering are jagged. This indicates a lack of proper "underlay"—the foundational stitching that stabilizes the fabric before the top layer is applied.

When a client observes these defects, even subconsciously, the immediate association is carelessness.

The elo works Standard: Analyzing "Exhibit A"

Contrast the previous example with Exhibit A. This is the standard we adhere to for all custom branded uniforms, whether for a small startup or a multinational corporation.

Achieving this result requires precise machine calibration specific to the garment's fabric weight and texture.

High Stitch Density: We utilize a higher stitch count to ensure total coverage. The logo sits on top of the fabric, rather than sinking into it.

Structured Underlay: Before the visible logo is stitched, a structural framework is sewn to prevent the fabric from puckering or distorting.

Crisp Edge Definition: The lettering is legible and sharp, projecting an image of precision and authority.

The Business Case for Premium Uniforms

Why does this matter? Because your brand image is binary: it is either enhancing your reputation or degrading it.

If your team enters a negotiation wearing custom branded uniforms with fraying, low-density logos, you are starting at a deficit. You are asking a client to trust you with their business when you have evidently neglected the details of your own. You can explore the exact types of high-quality items we offer in Our Full Product Range today.

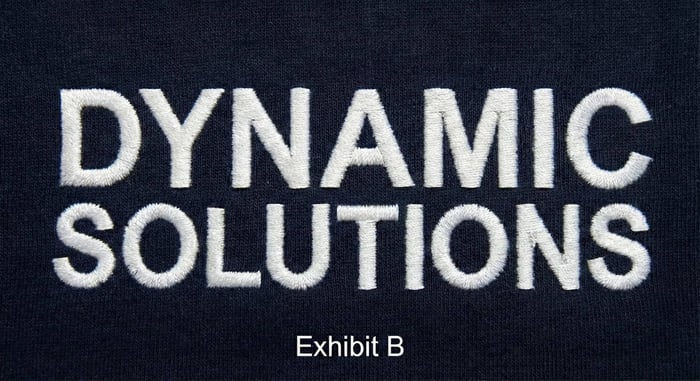

The Audit

We advise a simple audit of your current inventory. Examine the branding on your current team wear. Look closely at the tension and the density. If it resembles Exhibit B, your current vendor is prioritizing their speed over your brand integrity.

Contact elo works today. Let us ensure your custom branded uniforms are engineered to the same high standards as the services you provide.