In workwear, workwear consistency doesn’t fail by accident. It breaks when garment colors shift, logos lose accuracy in printing or embroidery, and repeat orders no longer match what came before. These small inconsistencies quietly damage brand image, often without anyone noticing—until it’s too late.

The Real Problem Isn’t Embroidery Alone

Most buyers assume quality issues come down to embroidery skill.

That’s only part of the picture.

In reality, workwear failures usually happen across three connected areas:

Garment color inconsistency

The same polo or hoodie ordered months later appears slightly lighter, darker, or warmer in tone.Logo color inaccuracy (print & embroidery)

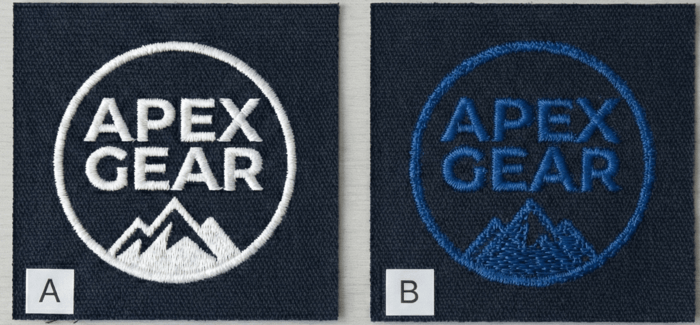

Printed logos drift from brand colors.

Embroidered logos lose definition, density, or exact shade matching.Repeat-order drift

Even when the first order looks fine, the second or third order no longer matches — despite using “the same specs.”

This is not random.

It’s structural.

Why Fashion Manufacturers Struggle With Workwear

Most clothing manufacturers are built for one-time production, not long-term consistency.

Workwear requires:

Locked fabric dye standards

Controlled logo color references

Documented embroidery parameters

Repeatable production systems

Without these controls, consistency depends on memory, staff turnover, or manual judgment.

That is not a system.

That is a risk.

Why Inconsistency Damages Brands Quietly

Poor workwear quality doesn’t always look “bad.”

It looks almost right.

That’s what makes it dangerous.

• Teams wearing slightly different shades

• Logos that look fine up close but cheap over time

• Gifts that feel less premium than intended

These details don’t cause complaints.

They cause lost confidence.

Brand perception erodes quietly — internally and externally.

Why Repeat Orders Are Where Workwear Consistency Breaks

Most workwear problems don’t appear on the first order.

They appear on the second or third.

The initial sample is usually handled with extra care. Colors are checked, logos are reviewed, and embroidery looks acceptable. But when time passes and a reorder is placed, cracks begin to show.

Fabric dye lots change.

Printing inks are mixed by eye instead of reference.

Embroidery files are reused without verifying stitch density or placement.

The result is subtle inconsistency.

A hoodie that looks slightly darker.

A logo that feels thinner.

A polo that doesn’t quite match the original batch.

For teams that grow, this creates visible mismatch.

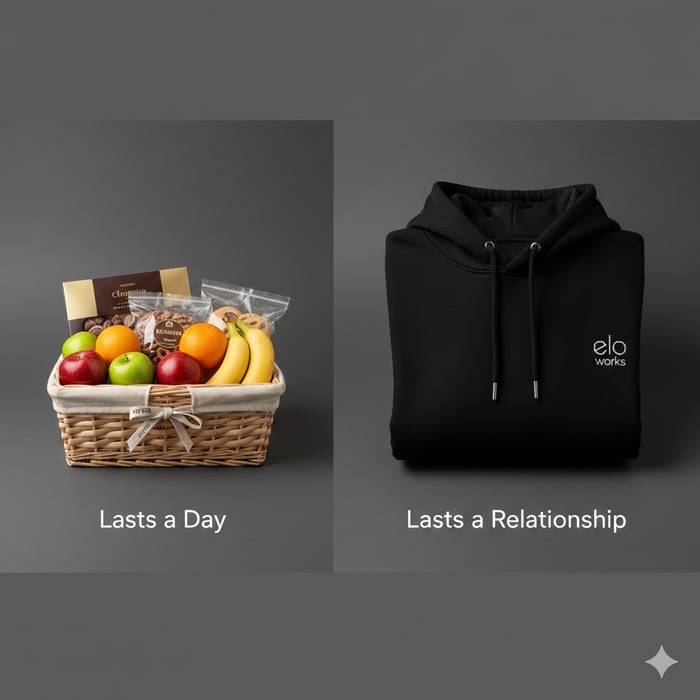

For corporate gifts, it weakens perceived quality.

True workwear consistency means treating every reorder as a controlled reproduction—not a fresh guess.

One Rule Every Buyer Should Use

Here is a simple rule that protects brands:

If your supplier cannot guarantee consistent garment color, accurate logo reproduction (print and embroidery), and identical results across repeat orders — you do not have a supplier. You have a liability.

Workwear is not decoration.

It is a long-term brand asset.

Assets require systems, not promises.

What True Workwear Expertise Looks Like

At elo works, workwear consistency is not assumed — it is engineered.

That means:

Controlled fabric sourcing and color tracking

Accurate logo color matching across print and embroidery

Logged embroidery density, stitch type, and placement

Repeat-order documentation so nothing “drifts” over time

This is how global workwear brands operate.

Anything less is guesswork.

The most expensive uniform mistakes are not obvious.

They are subtle.

They repeat.

And they compound over time.

If you care about how your brand shows up every day — on your team and in the hands of your clients — consistency is not optional.

Planning a workwear order or a repeat run?

Before committing, make sure your supplier can guarantee consistency — not just the first time, but every time.