Introduction

In workwear, workwear consistency is tested most severely when timelines are tight.

Anyone can promise speed.

Very few can deliver speed without compromising garment color, logo accuracy, and finish quality — especially on repeat or reference-based orders.

This case involved 100 embroidered jackets for Baker Tilly – Faisalabad office, coordinated with Mr. Ahsan Rasheed, Partner, under a fixed internal deadline.

Seven days.

No flexibility.

No tolerance for inconsistency.

The Real Challenge Wasn’t Speed

Fast production is not unusual.

What makes workwear difficult is delivering fast while maintaining consistency across:

Garment color

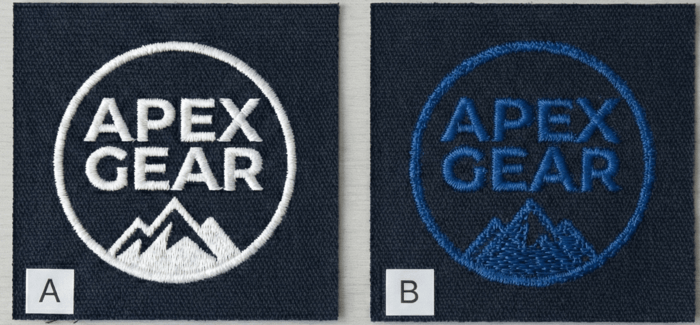

Embroidered logo accuracy

Printed logo color matching

Overall finish and professional appearance

The jackets needed to align with an earlier batch — not just visually, but technically.

This is where most suppliers fail.

Why Workwear Orders Break Under Time Pressure

Under tight deadlines, non-specialist manufacturers often take shortcuts:

Substituting fabric shades that are “close enough”

Reusing embroidery files without verifying stitch density

Adjusting print colors by eye instead of reference

Skipping verification steps to save time

These shortcuts usually become visible only after delivery — when corrections are no longer possible.

In workwear, this creates unnecessary risk.

How We Approached the Order

Before discussing timelines, we focused on locking workwear consistency.

That meant:

Verifying garment color against prior reference standards

Matching logo colors accurately across embroidery and printing

Confirming stitch density, placement, and finish

Executing production with zero substitutions

Every step was designed to protect repeatability, not just speed.

The Result

Seven days later, the jackets were delivered.

No color deviations

No logo inconsistencies

No rework required

No follow-up explanations needed

The order met both the deadline and the quality expectations.

This outcome was not accidental.

It was the result of systems built specifically for workwear.

The Lesson for Buyers

Speed without control is a liability.

If your supplier moves fast but cannot guarantee:

Consistent garment color

Accurate logo reproduction

Repeatable results across orders

Then speed will only magnify mistakes.

Workwear requires documented processes, controlled execution, and experience — not best guesses.

Final Thought

Workwear is not a one-time purchase.

It is a long-term brand decision.

Every jacket, polo, or uniform your team wears reflects your organization — internally and externally.

That is why workwear consistency matters more than promises, pricing, or speed alone.

Talk to Our Team

If you are planning a branded workwear order or a repeat run and need consistent garment colors, accurate embroidery, and reliable delivery, speak directly with our team.

Chat with us on WhatsApp to discuss your requirement